It is 2034. Tensions are on the rise in the Taiwan Strait. A small US reconnaissance team equipped with first-generation smart radios designed to operate in contested information environments is inserted onto a small island inside the adversary’s antiaccess / area denial zone. Simultaneously, other US forces begin to deploy in the area of operations with covert mobile precision-strike systems. The plan is to string together a dispersed sensor and precision-strike network to blunt adversary attacks and deter escalation.

Freedom of navigation operations during the crisis go awry and quickly escalate into a shooting conflict. But for those that need to do the shooting, the first few hours of the conflict do not go well. Sending and receiving information between the recon teams, other sensors, and the fire support assets does not happen. Something has gone terribly wrong.

A previously unknown Assassin’s Mace capability has disrupted radio signals, leaving only unintelligible static. The good news is that analysts in theater are quickly able to understand the nature of the interference and realize that a small adapter can be added to the antenna to restore communications. But now comes the difficult part: determining how to design and build tens of thousands of these completely new parts and distribute them to US forces like the small reconnaissance team cut off in a denied environment.

Welcome to combat logistics in the age of systems-confrontation warfare, where rapidly designing, producing, and deploying wartime combat resources while defending against complex systems-confrontation attacks on US logistics systems becomes the norm.

Warfare Changes, but the Value of Logistics Remains

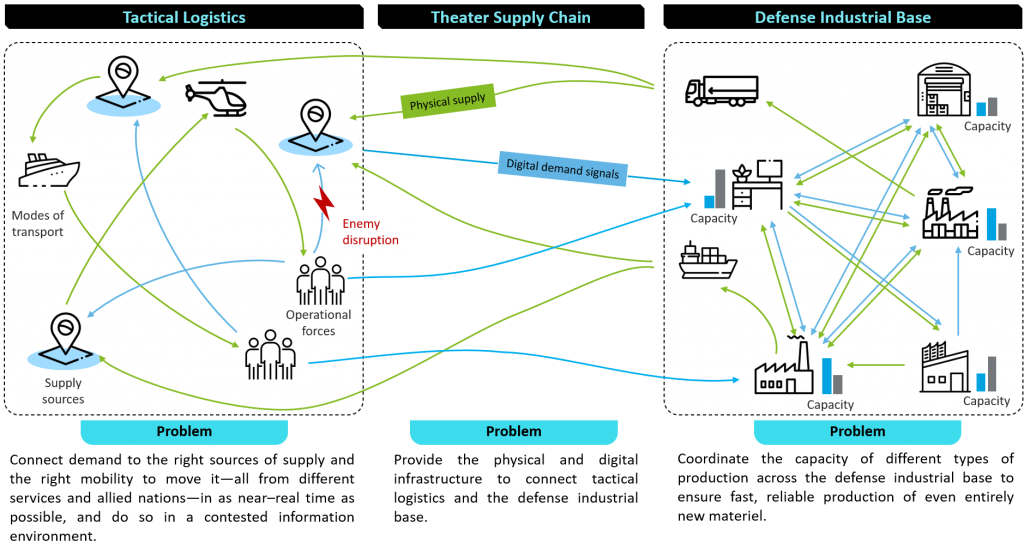

Logistics has always mattered in warfare. Alexander the Great allegedly said that if his campaign should fail, his logisticians were the first to be punished. Nothing about the way wars will be fought in the future will change the importance of logistics. What will change is how militaries conduct logistics operations. For the United States and its allies, rethinking logistical practices against peer adversaries waging systems-confrontation warfare specifically designed to counter friendly capabilities means abandoning reliance on some familiar capabilities such as linear supply chains. The United States and its allies should create interconnected physical-digital networks that can not only pair demand with supply and mobility at the tactical edge but also coordinate production capacity in real time for the industrial base. This is not a new concept—commercial industries have been using such digital supply networks for the past few years—but it is new at the scale demanded by great power warfare. In essence, winning a great power conflict depends on creating systems combat logistics to succeed in a systems-warfare environment.

Why is Logistics so Hard in Great Power Warfare?

Many more spaces will be contested. Systems warfare is a strategy to disrupt, disable, and destroy an adversary’s operational systems that enable military functions—command and control, information, intelligence, fires, movement and maneuver, protection, and sustainment. To put it simply, a modern military operates through a system of systems. From battle networks to supply chains, operations depend on systems of communications, data, and physical and digital infrastructure all working together. Therefore, disrupting or disabling such a system requires an ability to deploy cyber, electronic warfare, information operations, and conventional kinetic-strike capabilities across all operational domains. Done right, an effective system destruction campaign can paralyze an adversary by obstructing the digital and physical links connecting troops, weapons, resources, and leaders at a scale and speed not yet seen in warfare.

Contested spaces will persist. To defeat an adversary, warfare typically reflects strategies of annihilation, exhaustion, or attrition. But as Andrew Krepinevich Jr. points out, in protracted great power warfare between nuclear powers—which is what the United States should be prepared to fight unless it is willing to vertically escalate to mutually assured destruction—neither annihilation nor attrition are likely options, leaving exhaustion the most probable course. Assuming a strategy of exhaustion requires time to exhaust one’s adversary and having the resources (i.e., beans and bullets) necessary to do so.

Avoiding exhaustion and persisting in great power warfare defined by systems destruction means current US logistical and industrial base practices simply will not work. The People’s Liberation Army‘s (PLA) long-range precision-strike capabilities are designed specifically to prevent the United States from establishing a logistical advantage prior to combat operations. The current US reliance on pre-positioned stockpiles would be static and vulnerable in war with a peer. Moreover, cyberattacks can cripple industrial capacity, from production to distribution, regardless of distance. Indeed, the ability to reduce the significance of geography through cyber and other systems-destruction attacks, combined with the attack range of the PLA Rocket Force, means consolidating large quantities of essential combat resources in any one area poses an incredible risk to US military operations. This is why relying purely on US logistics and industrial capacity will be a quick path to exhaustion. Rather, integration of allies both at the tactical edge and in the industrial base will be critical to lasting through a great power war.

Logistics in a Contested Environment

If the nature of great power warfare makes many of the most familiar logistical approaches risky, what will logistics look like in a contested environment? To better understand, let’s return to our reconnaissance team.

Coordinating Capabilities at the Tactical Edge

Assuming that the team was able to stay hidden from adversary observation and that attempting to communicate via radio will either fail due to radio frequency disruption or reveal the team’s position, delivering them supplies will have to rely on a mix of real-time measurements and predictive demand signals. This goes well beyond just multiplying two MREs a day times the number of personnel to determine when a unit will need another Class I resupply. It involves using sensors to measure everything from water to repair parts to ammunition counts and then feeding that data into algorithms that include estimates for future operations to allow commanders to proactively resupply units exactly when they need it—no running out of critical spare parts and no needing to stockpile ammunition.

But predicting troop needs is only helpful if there are supplies to send and the means to send them. When dealing with bulky items like fuel or HIMARS rockets, finding and delivering those supplies into a contested environment is no easy task. The solution rests on not going it alone. Networking allied and partner capabilities can inform commanders as to who has what resources and where. These dispersed resources can then be paired to a network of available trucks, aircraft, boats, submarines, drones, or just about anything else that moves to deliver the supplies where and when they are needed.

In this way, the tactical edge is all about coordinating capabilities. You need to find out who needs what, who has what, and who has the capability to deliver what. Then you need to solve that multiple-variable equation for the optimal solution. That solution demands many tools—smart algorithms, significant data management, sharing across partners, and an ability to operate in both connected and disconnected modes—but above all it demands a full view of the battlespace that integrates the operational and logistical pictures.

Connecting the Edge to the Base with Theater Supply

Delivering geographically dispersed goods to troops through theater supply would require a coordination system that can match logistical supply to operational demand. This approach resembles a gig transportation service that matches demand for rides with a supply of drivers. The military analog would not just connect riders (operational forces) with drivers (sources of supply) but also drivers to car dealers and manufacturers (theater logistics and the defense industrial base) to make sure the right types of vehicles are on the road. At the theater and industrial base level, such a capability would introduce unheard of flexibility and adaptability. At the tactical edge, there would be benefits from achieving predictable levels of supply to units without routines that could be targeted.

For the reconnaissance unit, this could mean using autonomous disposable semisubmersibles (e.g., devices like a drug sub) or stealthy drones that are available at the moment of need, and thus capable of delivering goods quickly and without putting more troops in harm’s way. Moving larger volumes of goods outside contested areas of operation could simply mean leveraging existing commercial and military ships, planes, trains, trucks, vans, and anything else capable of carrying supplies. All these various gig logistics transport vehicles would need to be networked together to show which are available and where so that as demand for transport arises, there is no delay in moving goods toward their destination. The value in this approach for theater supply means resources arrive at their destination faster while complicating the adversary’s opportunity to attack supplies by increasing the number and variety of logistics pathways. However, it does require that all users be able to draw from the same pool of real-world data, while only seeing what they need to see at their echelons and what their roles entitle them to see.

Coordinating Capacity in the Industrial Base

Moving large capabilities or supplies through theater supply to the tactical edge can be challenging but it does not require the production of completely new items. Warfare often results in urgent needs for new equipment—like the radio antenna adapters for our fictional reconnaissance team. That new equipment means new demands for the defense industrial base.

The central question for new production in the defense industrial base is one of coordinating capacity. When it comes time to mass-produce known or new items for the military, government buyers and prime contractors need to know who has the available manufacturing capacity to make what is needed. This extends to allied production capacity. Understanding which country can produce what and where is a product of being coordinated through a digital supply network. If a US ammunition factory is hit by a malware attack that stalls production, a factory in a partner nation could know nearly instantaneously to ramp up production of ammunition given the network information flowing between them. This also means the adversary now has a moving target if it wants to continue to disrupt production.

This level of coordination will only be possible if the industrial base continues to adopt the technologies of the digital thread—creating a single source of digital truth from design through production and sustainment. In effect, the digital thread allows production to be dispersed across different producers in different countries to meet demand, and guarantees that it will all work when brought together at the tactical edge. The same production processes that create agile software today can be applied to the defense industrial base. Freedom’s forge will become freedom’s software factory.

Making Necessary Changes

The story above is fictional but the needs are very real. The good news is that the tools to meet these needs are also very real. They are powering the Fourth Industrial Revolution around the world. But recasting military logistics in the mold of a digital supply network will require new technology solutions and new people solutions.

The Tech Solution—A Digital Backbone

Digital supply networks require a digital backbone, a single digital platform that can combine operational and logistical data at the tactical edge and military and enterprise data in the industrial base. Industry has created many different platforms to handle the volume and variety of data that flows between producers, logisticians, and customers. Take e-commerce sites as an example; not only do they sell their own products, but they also serve as a hub to connect the needs of customers to other producers.

The military will also need redundancies in these systems because, despite its best efforts, a peer adversary will likely be able to disrupt or destroy some parts of the network. Importantly, this digital backbone needs to be produced with allies and partners from the start to allow for the seamless sharing of data based on echelon and clearance. Research into data sharing in everything from commercial aviation to maritime ports suggests that data sharing—even amongst commercial competitors—is possible; it just needs to be built into the design from the start.

The People Solution—Closer Planning, More Practice

The need for the digital backbone will also change how people need to work. For example, commanders used to constant communications and full-motion video of their units’ operations will not be able to rely on such practices in the future. Rather, they will need to shift their leadership styles to governance and oversight using commander’s intent. This returning leadership style requires delegating operational intent and allowing teams to make tactical decisions to meet that intent. For industrial or logistical capabilities, this could mean commanders give logisticians and industry partners “service-level agreements” that spell out how different priorities are to be resourced and leave it to them to determine how best to make and transport those needed items amid a rapidly changing environment.

Similar shifts will need to take place at national levels as well. An international digital backbone will operate on 1s and 0s first and on trust second. A country at war is not likely to send another its last supply of ammunition or retool a factory on a dime if there is not mutual trust. While the United States enjoys many long-standing alliances, relationships have not always been as strong or as coordinated as they could be. Working to establish a joint and combined digital supply network relationship for the tactical edge should be a first step. Thereafter, the joint and combined network should include broader logistical capabilities, and finally, the industrial base. At each phase, the focus should be on developing trust and aligning capabilities.

Finally, the United States, its allies, and partners (government and industry alike) must practice. The US military knows logistics are difficult. It would be foolish to expect new systems and operational concepts to work perfectly the first time and under fire. Military logistics exercises of various scales and intensity should be routine. The focus should not only be to ensure the network works, but to improve it as technology and the strategic environment change. There is no substitute for real-world, full-force exercises, but digital twins can be helpful to be better prepared for the complexities of great power warfare.

The end state is not to produce a new logistics system as if it is a static-state product. Instead, the goal is to produce a new way of conducting military logistics through the understanding that in systems warfare, a complex system of systems will need to evolve in lockstep with advancements in technology, military strategy, and adversaries. While the purpose of such a logistics system is to ensure US victory in a near-peer war, it also serves an important role in deterring adversaries from fighting in the first place. Through a military digital supply network operating as a system of systems, the United States can deny its adversaries the ability to disrupt wartime logistics, forcing any peer adversary to contemplate the feasibility of exhausting the United States. In deterring war and being more prepared in the event of one, a digital supply network provides the advantage the United States requires.

Alan Estevez is a specialist executive with Deloitte Consulting LLP. Alan had a thirty-six-year career with the Department of Defense including serving as the principal deputy under secretary of defense for acquisition, technology, and logistics from 2013 to 2017 and as the assistant secretary of defense for logistics and materiel readiness from 2011 to 2013.

Kelly Marchese leads Deloitte Consulting LLP’s Supply Chain and Network Operations practice for the Government & Public Services market. Kelly specializes in global supply chain transformations, supply chain innovation/advanced technologies, lean operations, and supply chain risk/resilience. She was on the Supply Chain Board for Howard University and is the lead university partner for Duke. Kelly is a leader in the Supply Chain and Manufacturing Operations Women’s Initiative (WIN) Group.

Adam Routh is a research lead with Deloitte’s Center for Government Insights and a PhD candidate in the Defence Studies Department at King’s College London. His research areas include the future of warfare and defense. Adam previously worked for the Defense Program at the Center for a New American Security. He also served as a team leader with the US Army’s 75th Ranger Regiment.

Joe Mariani is a research lead with Deloitte’s Center for Government Insights. He leads research into defense, security, and justice topics with an emphasis on technology adoption, innovation, and the internet of things. Previously, he served as a Marine Corps intelligence officer and federal consultant.

The views expressed are those of the authors and do not reflect the official position of the United States Military Academy, Department of the Army, or Department of Defense.

Image credit: Sgt. Michael J. MacLeod, US Army

Very few references. Invalid and illogical rationale. What about the fact that the US Marines have criticized vaccines? What about the fact that Microsoft is unreliable and requires military programmers to be useable? What about the fact that corporations are unreliable? Inadequate analysis! Some sound points were made, e.g. that military and industrial coordination is essential, but you failed to criticise that relationship. What about the fact that high tech abilities failed to defeat the Taliban??? After 20 years of war! You overestimate the power of AI and you underestimate the value of human capital. E.g. Israel and their false flags like ISIS and HAMAS!!! Not even mentioned??? That massively complicates intelligence and logistics! I award you a D+ and I'm being kind. Inadequate analysis! Even a mention of the political complications would have earned you an extra level. What about the problems of AI and future cybernetics? Etc etc